A feeder belt is an essential component in the paper, cardboard, packing, and printing industry. It plays a crucial role in the smooth and efficient operation of various machines and processes involved in these industries.

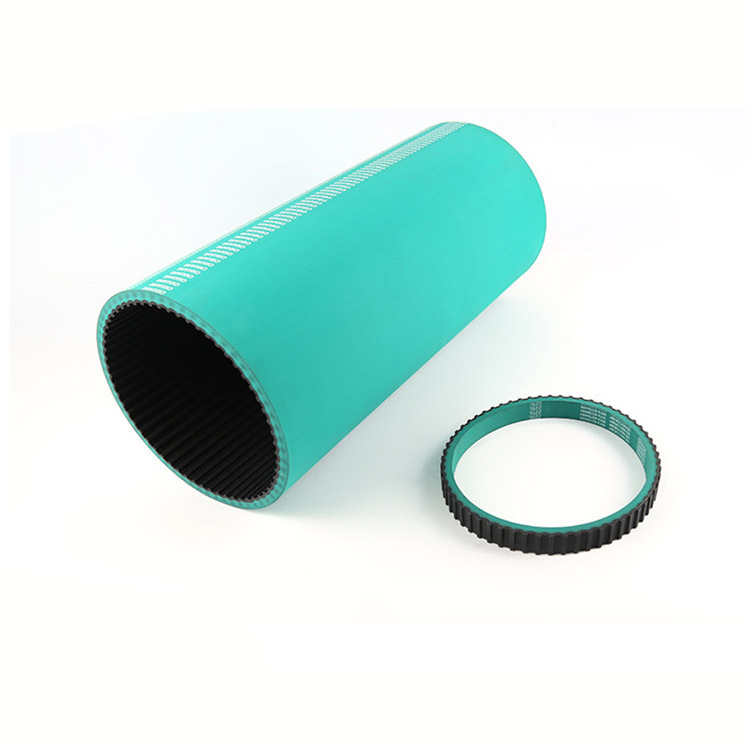

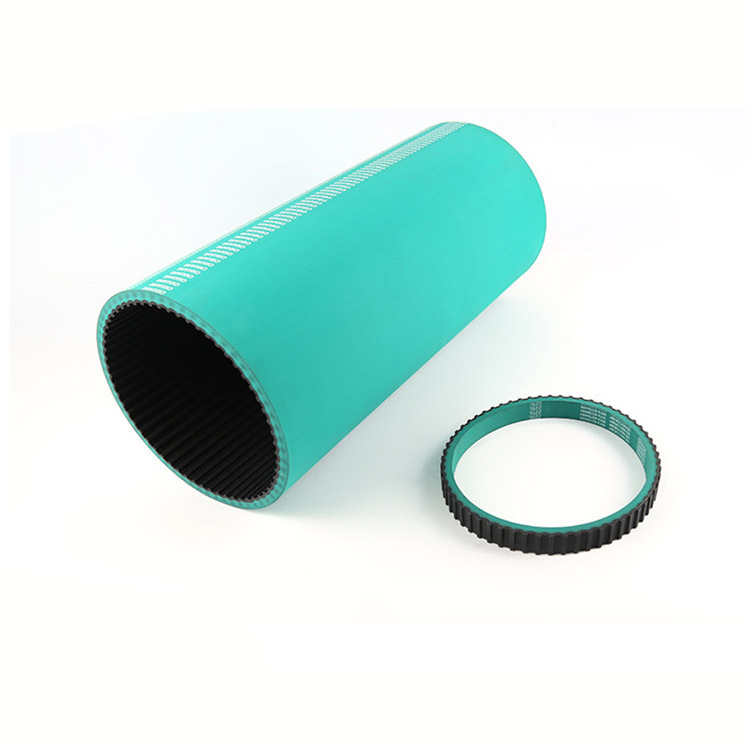

The inner ring is a standard synchronous belt tooth shape or flat belt, generally H, L, HTD3M, HTD5M, HTD8M, S8M and other models, with 3-15mm different thickness of color vulcanized on the back of the belt, and the hardness is appropriately reduced,usually 45 shoreA. It is mainly used to drive or convey items, and can be used in conveyors, dishwashers, dryers, packaging machinery, food machinery, and other industries.

With back cover material, generally use NR or Linatex. The colors are: black, white, green, blue, yellow, red or more.

The product features ensure high tensile strength, high transmission accuracy, good stability, oil resistance, low noise, etc. Model specifications and parameters

The feeder belt is primarily responsible for transporting and feeding paper, cardboard, and other materials to different machines and equipment. It ensures a continuous flow of materials, preventing any interruptions or delays in the production process. This is particularly important in high-volume manufacturing facilities where efficiency and productivity are paramount.

Feeder belts are designed to be durable and resistant to wear and tear. They are made from high-quality materials such as rubber or synthetic compounds, which provide excellent grip and traction. This allows the belt to withstand the heavy loads and constant movement associated with the paper, cardboard, packing, and printing industry.

In addition to its primary function of material transportation, the feeder belt also contributes to the overall quality of the finished products. It ensures accurate positioning and alignment of the materials, which is crucial for precise cutting, folding, and printing processes. A well-maintained and properly adjusted feeder belt can significantly improve the accuracy and consistency of the final products.

A feeder belt is an essential component in the paper, cardboard, packing, and printing industry. It plays a crucial role in the smooth and efficient operation of various machines and processes involved in these industries.

The inner ring is a standard synchronous belt tooth shape or flat belt, generally H, L, HTD3M, HTD5M, HTD8M, S8M and other models, with 3-15mm different thickness of color vulcanized on the back of the belt, and the hardness is appropriately reduced,usually 45 shoreA. It is mainly used to drive or convey items, and can be used in conveyors, dishwashers, dryers, packaging machinery, food machinery, and other industries.

With back cover material, generally use NR or Linatex. The colors are: black, white, green, blue, yellow, red or more.

The product features ensure high tensile strength, high transmission accuracy, good stability, oil resistance, low noise, etc. Model specifications and parameters

The feeder belt is primarily responsible for transporting and feeding paper, cardboard, and other materials to different machines and equipment. It ensures a continuous flow of materials, preventing any interruptions or delays in the production process. This is particularly important in high-volume manufacturing facilities where efficiency and productivity are paramount.

Feeder belts are designed to be durable and resistant to wear and tear. They are made from high-quality materials such as rubber or synthetic compounds, which provide excellent grip and traction. This allows the belt to withstand the heavy loads and constant movement associated with the paper, cardboard, packing, and printing industry.

In addition to its primary function of material transportation, the feeder belt also contributes to the overall quality of the finished products. It ensures accurate positioning and alignment of the materials, which is crucial for precise cutting, folding, and printing processes. A well-maintained and properly adjusted feeder belt can significantly improve the accuracy and consistency of the final products.