Polytetrafluoroethylene (PTFE) belts are widely recognized for their excellent performance in various industrial applications. As a highly versatile material, PTFE offers numerous benefits, including high temperature resistance, non-stick properties, and chemical inertness. Unibelt is a leading conveyor belts manufacturer, we specialize in providing a range of high-quality conveyor belts, including light duty conveyor belts, rubber conveyor belts, rubber timing belts, flat transmission belts, wire mesh conveyor belts, and plastic modular belts. This article explores the diverse applications of PTFE belts and highlights why they are an essential component in many industrial processes.

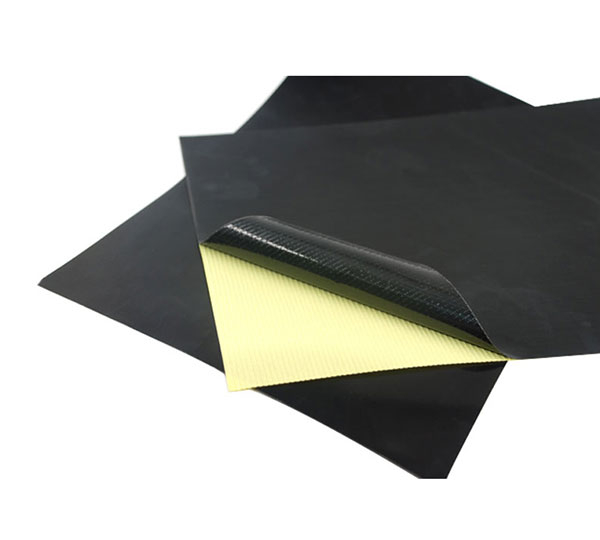

PTFE belts are made from polytetrafluoroethylene, a synthetic fluoropolymer of tetrafluoroethylene, commonly known by the brand name Teflon. PTFE is renowned for its unique properties, such as high resistance to heat, chemicals, and electrical conductivity, as well as its low friction and non-stick surface. These characteristics make PTFE an ideal material for conveyor belts used in demanding industrial environments.

High Temperature Resistance: PTFE belts can withstand temperatures ranging from -73°C to 260°C (-100°F to 500°F), making them suitable for high-temperature applications.

Non-Stick Surface: The non-stick properties of PTFE prevent materials from adhering to the belt, reducing the risk of contamination and making cleaning easier.

Chemical Resistance: PTFE is highly resistant to a wide range of chemicals, including acids, bases, and solvents, ensuring durability and longevity in harsh environments.

Low Friction: The low friction coefficient of PTFE reduces wear and tear on the belt and minimizes energy consumption during operation.

Flexibility: PTFE belts offer excellent flexibility, allowing them to be used in various conveyor systems, including those with complex curves and inclines.

PTFE belts are used in a wide range of industries due to their exceptional properties. Here are some of the primary applications:

Food Processing

In the food processing industry, maintaining hygiene and safety standards is paramount. PTFE belts are ideal for food processing applications due to their non-stick surface and resistance to high temperatures and chemicals. They are commonly used in baking, drying, and freezing processes.

Baking: PTFE belts are used in baking ovens for conveyorized baking of bread, pastries, and other baked goods. Their non-stick surface ensures easy release of baked products.

Freezing: In freezing applications, PTFE belts withstand extreme cold temperatures without becoming brittle, ensuring reliable performance.

Drying: They are also used in dehydrators and drying tunnels, where their heat resistance and non-stick properties are advantageous.

Textile Industry

The textile industry requires belts that can handle high temperatures and chemicals used in dyeing and finishing processes. Including:

Dyeing: PTFE belts resist the harsh chemicals and high temperatures involved in dyeing processes, ensuring long-lasting performance.

Finishing: In finishing applications, it provide a smooth, non-stick surface for heat setting and curing processes.

Packaging Industry

In the packaging industry, efficiency and cleanliness are critical. PTFE belts are used in packaging machines for their non-stick properties and chemical resistance.

Sealing: They are used in heat sealing machines for sealing plastic bags and pouches. Their high temperature resistance ensures effective sealing without sticking.

Conveying: PTFE belts are used in conveyor systems for transporting packaged goods, ensuring smooth and contamination-free movement.

Printing Industry

The printing industry utilizes PTFE belts for their durability and resistance to chemicals and high temperatures.

Screen Printing: PTFE belts are used in screen printing machines to transport materials through the printing process, providing a stable and heat-resistant surface.

Drying: In drying applications, they handle the high temperatures required to cure inks and coatings.

Electronics Industry

The electronics industry demands precision and cleanliness in manufacturing processes. PTFE belts are used in the production of electronic components for their non-stick surface and chemical resistance.

PCB Manufacturing: PTFE belts are used in the production of printed circuit boards (PCBs) for conveying and processing materials through etching and soldering stages.

Component Assembly: They are also used in conveyor systems for assembling electronic components, ensuring smooth and contamination-free handling.

Selecting the appropriate PTFE belt for your application involves considering several factors to ensure optimal performance. Here are some key considerations:

Assess the temperature range of your application to choose a PTFE belt that can withstand the required temperatures without degrading or losing performance.

Consider the types of chemicals the belt will be exposed to and choose a PTFE belt with the necessary chemical resistance to ensure longevity and reliability.

Evaluate the load and tension requirements of your application to select a PTFE belt that can handle the mechanical stresses without stretching or breaking.

Determine the surface properties needed for your application, such as non-stick characteristics or friction levels, to choose the most suitable PTFE belt.

Consider the conveyor system’s design, including belt width, length, and configuration, to ensure the PTFE belt fits and functions correctly within your setup.

As a leading conveyor belts manufacturer, Unibelt is dedicated to providing high-quality PTFE belts and other conveyor solutions tailored to meet diverse industrial needs. Here’s why you should choose Unibelt:

Unibelt offers a wide range of conveyor belts, including light duty conveyor belts, rubber conveyor belts, rubber timing belts, flat transmission belts, wire mesh conveyor belts, and plastic modular belts. Our diverse product line ensures that you can find the perfect solution for your specific application.

We use only the highest quality materials in our PTFE belts to ensure durability, reliability, and superior performance. Our belts are designed to withstand the rigors of demanding industrial environments.

We understand that each application has unique requirements. Unibelt provides customization options to tailor our PTFE belts to your specific needs, ensuring optimal performance and efficiency.

With years of experience in the industry, our team of experts is dedicated to providing technical support and guidance to help you choose the right PTFE belt for your application. We are committed to ensuring your satisfaction and success.

Unibelt is at the forefront of innovation, continuously developing new technologies and solutions to meet the evolving needs of our customers. Our commitment to research and development ensures that we provide cutting-edge products and services.

PTFE belts are indispensable in various industries due to their exceptional properties, including high temperature resistance, non-stick surface, and chemical inertness. Understanding the applications and benefits of PTFE belts can help you choose the right solution for your needs.

Choose Unibelt for your PTFE belt needs and experience the difference that quality, innovation, and expertise can make in your industrial processes.