Light duty conveyor belt are an important component in many industries, especially in material handling and transportation. It refers to a type of conveyor belt that is suitable for carrying lightweight materials and products. The belt's design and construction are specifically tailored to handle items that do not exceed a certain weight limit, typically ranging from 200 to 500 pounds per square inch (psi). In this article, we will discuss the key things you need to know about light duty conveyor belts.

1. Types of light duty conveyor belts

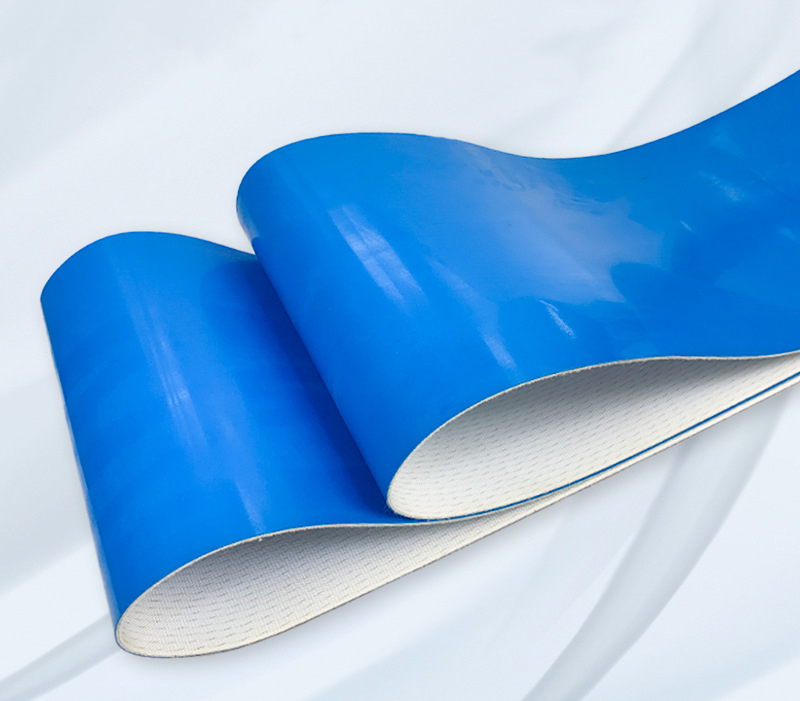

There are several types of light duty conveyor belts available in the market, including flat belts, modular belts, cleated belts, and roller belts. The most commonly used type is flat belts, which are made of various materials such as rubber, PVC, and fabric. Modular belts, also known as plastic belts, are made of individual interlocking modules that can be easily replaced. Cleated belts have ridges or cleats on their surface to prevent products from slipping or falling off the belt. Roller belts use rollers to transport items, making them suitable for incline or decline applications.

2. Materials used in light duty conveyor belts

Light duty conveyor belts are made of various materials to handle different applications. The most common material used is rubber, which is durable, flexible, and offers good grip for transporting items. PVC, or polyvinyl chloride, is also commonly used as it is lightweight, low-cost, and resistant to chemicals and weathering. Other materials used include polyester, nylon, and fabric, which are suitable for applications that require high tensile strength and flexibility.

3. Applications of light duty conveyor belts

Light duty conveyor belts are used in a wide range of industries, including food and beverage, pharmaceutical, manufacturing, retail, and logistics. They are suitable for transporting products such as boxes, packages, and small parts. They can also be used in assembly lines and packaging operations to move items from one process to another. Additionally, light duty conveyor belts are used in airports and in the transportation of luggage and baggage.

4. Factors to consider when choosing a light duty conveyor belt

When selecting a light duty conveyor belt, it is important to consider several factors to ensure that it is suitable for the intended application. These factors include the product weight, size, and shape, the speed and incline of the conveyor system, the environment in which the belt will be operating, and the required belt tension. It is also crucial to consider any additional features, such as cleats, tracking guides, and coatings, that may be necessary for the specific application.

5. Maintenance and safety

Like any other machinery, light duty conveyor belts require regular maintenance to ensure efficient and safe operation. This includes conducting routine inspections, cleaning, and lubricating the belts, as well as replacing any worn or damaged components. It is also essential to follow safety protocols when operating the conveyor system, such as wearing appropriate personal protective equipment and avoiding loose clothing or jewelry that could get caught in the belt.

6. Advantages of light duty conveyor belts

Light duty conveyor belts offer numerous advantages, including their versatility, ease of installation, and cost-effectiveness. They are also highly customizable, allowing for different belt widths, lengths, and materials to suit specific applications. Additionally, they have a low profile, making them ideal for tight spaces or applications with limited overhead clearance. They also provide a smooth and consistent movement of products, reducing the risk of damage or jamming.

light duty conveyor belts play a vital role in many industries, providing a reliable and efficient method of transporting lightweight products. By understanding the different types, materials, applications, and maintenance of these belts, you can select the right one for your specific needs and ensure its safe and efficient operation.

Our lightweight nylon conveyor belt is designed for light-duty applications, offering exceptional strength and durability. Made from high-quality nylon fabric, this conveyor belt offers excellent impact resistance and can handle a variety of materials with ease. Its low stretch and high elasticity make it ideal for conveying small or delicate items without damaging them. With a smooth and low-profile design, this belt is also easy to clean and maintain, making it a popular choice in industries such as electronics, pharmaceuticals, and consumer goods.

1.What is the average lifespan of a light duty conveyor belt?

The average lifespan of a light duty conveyor belt can range from 2 to 5 years, depending on the frequency and intensity of use, as well as proper maintenance and care.

2.What industries commonly use light duty conveyor belts?

Light duty conveyor belts are commonly used in industries such as food and beverage, packaging, light manufacturing, and logistics. It can also be used in commercial and agricultural settings.

3.Are there any safety precautions to keep in mind when operating a light duty conveyor belt?

Yes, it is important to follow all safety precautions provided by the manufacturer, including avoiding contact with moving parts, keeping loose clothing or hair away from the belt, and properly securing and guarding the conveyor system.

4.How do I clean and maintain a light duty conveyor belt?

Cleaning and maintenance procedures may vary depending on the material and design of the belt. Generally, it is important to regularly remove any debris or material build-up and to lubricate the belt and its components as recommended by the manufacturer.

5.Can a light duty conveyor belt be used for curved or spiral conveying?

Yes, some light duty conveyor belts can be used for curved or spiral conveying, but the design and material of the belt will depend on the specific application and curvature of the conveyor.