In the dynamic world of material handling, conveyor belt play an indispensable role in streamlining processes and enhancing efficiency. Unibelt stands at the forefront of this technology, offering innovative solutions tailored to diverse industry needs. This comprehensive guide explores the basics of conveyor belts, their types, applications, and essential considerations when selecting the right conveyor belt for your operations.

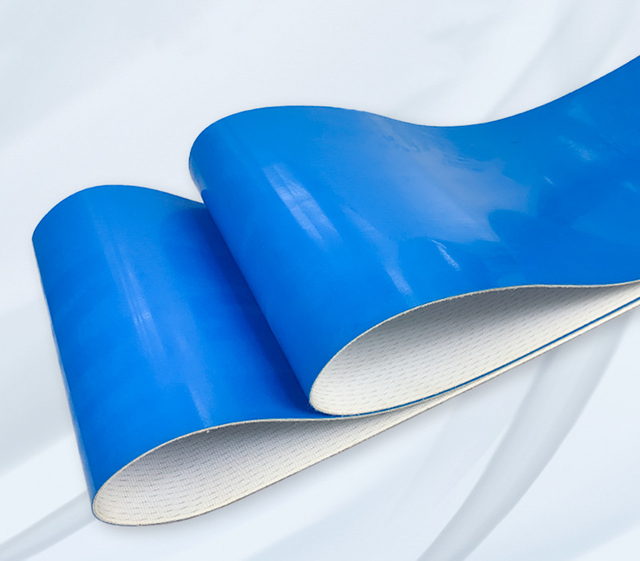

A conveyor belt is a continuous loop of material that rotates over pulleys and is used in various applications to move goods and materials from one place to another. It is typically made of two or more layers, commonly referred to as plies, with the outer layers made from durable materials like PVC or rubber, and the inner layer consisting of fabric materials like polyester, nylon, or cotton to provide structural strength and shape.

Flat belts are widely used in industries such as packaging, agriculture, and electronics. They are characterized by a flat surface that is ideal for transporting regular and irregular shaped objects. Flat belts can be operated in straight or curved paths and are praised for their simplicity and efficiency.

Modular belts consist of single pieces of plastic that interlock to form a conveyor surface. These are highly versatile and can be used in applications involving corners or sharp bends. Unibelt’s modular conveyor belts are known for their ease of maintenance and their ability to handle various products gently.

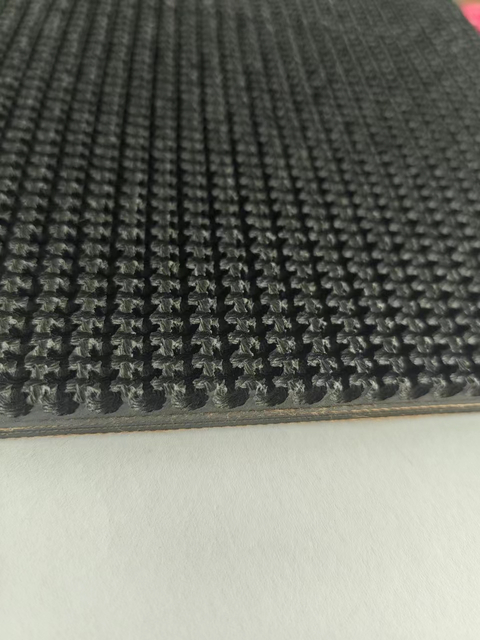

Cleated belts feature raised sections known as cleats that aid in transporting materials up an incline or through steep angles. These belts are particularly useful in industries where preventing product rollback is critical, such as food processing or mining.

Depending on the application, some conveyor belts need special properties like resistance to high temperatures, anti-static features, and food-grade materials. Unibelt specializes in creating belts with specific properties tailored to meet exacting industry standards.

Conveyor belts find their use in countless applications across various industries:

Manufacturing: Moving raw materials, components, and finished goods through different stages of the production process.

Packaging: Facilitating the orderly handling of products for packaging and distribution.

Mining: Transporting minerals from deep underground to the surface.

Agriculture: Used for transporting grain, vegetables, or other agricultural products during harvesting or processing.

Food Processing: Essential in moving food products through various phases of processing while adhering to hygiene standards.

Airports: For baggage handling systems that move luggage to and from aircraft.

Understanding the type of materials to be transported is crucial. Factors such as weight, size, and the potential for abrasiveness or corrosiveness impact the choice of conveyor belt material. For instance, heavier items might require belts with higher tensile strength and durability.

The environment in which the belt will operate influences the selection. For example, belts used in outdoor environments or extreme temperatures need to be specially designed to withstand such conditions. Conveyor belts used in freezer applications are manufactured to maintain flexibility at temperatures as low as -30°C.

The speed at which the belt operates is a critical consideration. Higher speeds require belts with better dynamic stability and low stretch properties. Unibelt designs belts that can handle speeds up to 500 meters per minute, ensuring high efficiency without compromising on safety or functionality.

Ease of maintenance and durability are important factors to reduce downtime and operational costs. Unibelt’s conveyor belts are designed for easy maintenance and long life, even under rigorous conditions, which reduces the total cost of ownership.

Certain industries, like food and pharmaceuticals, are governed by strict regulatory standards that dictate the type of conveyor belts that must be used. These belts must be non-toxic, easy to clean, and resistant to microbial growth.

Conveyor belts are a vital part of modern manufacturing and processing industries, offering numerous advantages in terms of efficiency, cost-effectiveness, and safety. As a leading conveyor belt manufacturer, Unibelt is committed to providing high-quality solutions that meet the varied needs of its customers. Whether you are transporting light goods in a clean environment or rugged materials in challenging conditions, Unibelt has the expertise and products to ensure your conveyor system runs smoothly and efficiently.